This instrument is used to measure the clearance rate of a certain amount of fine aggregates passing through a standard funnel and loaded into a standard container, which is called the angularity of fine aggregates, expressed as a percentage. It is suitable for measuring the angularity of fine aggregates used for pavement such as natural sand, artificial sand, stone chips, etc., to predict the influence of fine aggregates on the internal friction angle and resistance to flow deformation of asphalt mixtures.

The upper part is a metal or plastic cylindrical volumetric flask with a volume of 250mL, and the bottom is a metal inverted cone funnel with a height of 38mm, the angle is 60°±4°, and the diameter of the outflow hole is 12.7mm±0.6mm. A 100mL copper receiving container is placed under the analyzer with an inner diameter of 39mm and a height of 86mm. The container is embedded in a metal plate with a thickness of 6mm, and the container and the bottom plate are filled and consolidated with epoxy resin. There is a pit in the center of the bottom of the metal base plate to align with the base position.

1) Weigh the dry mass m0 of the fine aggregate receiving container.

2.)Fill the container with water, weigh the mass m1 of the water added to the cylinder, and calibrate the volume of the container V=m1-m0. At this time, the effect of temperature on the water density can be ignored.

3)The fine aggregate samples taken from the site are sieved with a standard sieve of 2.36mm or 4.75mm according to the maximum particle size, and the part larger than the maximum particle size is removed. Usually, a 2.36mm sieve is used for natural sand or machine-made sand and stone chips of 0-3mm specifications, and a 4.75mm screen can be used for 0-5mm machine-made sand and stone chips.

4.)Take a sample of about 2 kg and put it in an enamel plate, add water to soak for 24 hours, and wash it carefully so that the soil and dust are suspended in the water. Slowly pass the suspension through 1.18mm and 0.075mm sets of sieves several times to remove the suspended mixed water, rinse the aggregate with clean water, and carefully wash away the part smaller than 0.075mm. Pour the 1.18㎜ and 0.075㎜ sieves back into the enamel tray, put them in an oven at 105℃±5℃ to dry to constant weight, and mix them evenly after cooling. There are no less than 3 samples.

5) The funnel and the cylinder are connected to form a whole, and the receiving container is placed under the funnel. Cover the opening with a small glass plate.

6) Slowly pour the sample into the funnel from the top of the center of the cylinder (the height is flush with the top of the cylinder), and the surface is as flat as possible.

7) Remove the small glass plate blocking the funnel opening door. The fine aggregate in the funnel then flows out through the opening of the funnel into the receiving container.

8) Gently level the surface of the container with a bladed ruler without any vibration.

9) Weigh the total mass m2 of the container and fine aggregate, accurate to 0.1g.

10) Determine the gross volume relative density b of fine aggregate according to the method of T0330 of this regulation.

11) Three parallel tests were carried out, and the average value was taken as the test result of the angularity of the fine aggregate.

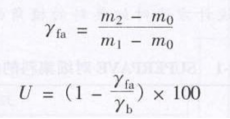

Calculate the bulk density and gap ratio of the fine aggregate in the container, accurate to 1 decimal place, and the gap ratio is the angularity of the fine aggregate

In the formula: γfa——the loose relative density of fine aggregate;

m0——empty mass of container (g);

m1——the total mass of the container and water (g);

m2——the total mass of the container and fine aggregate (g);

U——The gap ratio of fine aggregate, that is, angularity (%);

γb——The relative density of the gross volume of the fine aggregat

We will contact you within 1 working day, please pay attention to the email with the suffix “@gtj-test.com”.