| Model | WEW-600B |

|---|

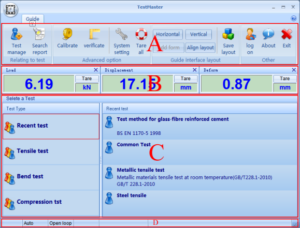

The series of test machines are loaded hydraulically. Electro-hydraulic servo control technology is used to test the tensile, compression, bending and shearing of metal and non-metal materials. It displays various closed-loop control methods such as curves, forces, deformations and displacements. The display can be switched at will in the test. It also has the functions of stress rate, strain rate and stress retention and strain retention.The data will be automatically stored.

FEATURE

○ The oil source control part adopts generator motor and digital digital valve

○ The space adjustment mechanism adopts Kawashima environmental protection machine, with low noise;

○Using semi-closed hydraulic jaws, with high strength;

○ Vertical control cabinet, touch industrial computer, convenient and practical, saving space;

○The test space structure of the main engine with four columns and double screws;

○ High-speed motion communication interface and PC communication;

○ Standard database management test data;

○ High-strength, high-strength, sub-view protective net for safety protection;

○ The Chinese and English interface can be switched freely, which is more convenient and faster for customers.

GBT、ISO、ASTM、DIN、JIS etc.

PRODUCT PARAMETERS

| Model | WAW-100B | WAW-300B | WAW-600B | WAW-1000B | ||

| Max. Test Force(KN) | 100 | 300 | 600 | 1000 | ||

| Tensile Space(mm) | 700 | 700 | 700 | 700 | ||

| Compression Space(mm) | 600 | 600 | 600 | 600 | ||

| Column Number | 6 | 6 | 6 | 6 | ||

| Compression Platen(mm) | Φ148 | Φ148 | Φ198 | Φ225 | ||

| Round Sample

Test Range(mm) |

Φ6~20 | Φ10~32 | Φ13~40 | Φ13~40 | ||

| Plat Sample Test Range(mm) | 0~20 | 0~10 | 0~13 | 0~13 | ||

| Compression Plant Size(mm) | 148 | 148 | 198 | 225 | ||

| Piston Stroke(mm) | 200 | 200 | 200 | 200 | ||

| Diameter of bending roller

(mm) |

50/50 | 50/50 | 50/50 | 50/50 | ||

| Bending fulcrum span(mm) | 50-300 | 50-300 | 50-300 | 50-300 | ||

| Effective Test Range | 1%-100%FS | |||||

| Machine Grade | Level 1/ Level 0.5 | |||||

| Relative indication error | ±1% | |||||

| Test Force Resolution | 1/300000 | |||||

| Stress Rate Control Range | 1MPa/s-50MPa/s | |||||

| Stress Rate Control Accuracy | 1/300000 | |||||

| Deformation Resolution | according to the number of selected encoder lines, the resolution for 3600 lines is 0.007mm | |||||

| Strain Rate Control Range | 0.00025/s-0.0025/s | |||||

| Strain Rate Control Accuracy | ±2% | |||||

| Displacement Resolution | according to the number of selected encoder lines, the resolution for 3600 lines is 0.007mm | |||||

| Displacement Rate Control Range | 0.1-100 | 0.1-150 | 0.1-180 | 0.1-220 | ||

| Displacement Rate Control Accuracy | ±2% | |||||

| Stress/Strain/Displacement Control Range | 1%-100%FS | |||||

| Stress/Strain/Displacement Control Rate | <10%FS: ±2%;>10%FS: ±1% | |||||

| Oil Control Cabinet(mm) | 600*740*1560 | |||||

| Host Size(mm) | 620*520*1723 | 810*560*1910 | 880*570*2050 | 940*640*2250 | ||

| Motor Power(kW) | 2.2 | 2.2 | 2.2 | 2.2 | ||

| Total Weight(kg) | 1650 | 1770 | 2150 | 2950 | ||

Touching screen computer equipped with Keyboard, Pencil and Mouse, English control buttons.

1. Using semi-closed hydraulic jaws, high strength.

2. Flat and V-shape jaw

3.6 pillers structure with high-toughness and beautiful protective net .

4.Siemens motor and high precision digital valveare used in the oil source control.

5.Kawashima reducer, low noise during the test.

6.High precious displacement transducerand pressure transducer

7.Bending fixture

8.Spherical Pressure Plate

-300x300.png)

We will contact you within 1 working day, please pay attention to the email with the suffix “@gtj-test.com”.