Concrete is the most widely used building material, and its quality is closely related to the safety of building structures. Various countries have done a lot of research in the measurement and evaluation of concrete performance, and have formulated corresponding test standards. American standard ASTM C39 “Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens”; European Standard EN 12390 “Hardened Concrete Test” series of standards.

GB/T50081-2019 “Standard for Test Methods for Physical and Mechanical Properties of Concrete” is the main test method for mechanical properties of concrete in China. The standard includes 5 test methods for the mechanical properties of concrete for cubic and prismatic specimens and 4 test methods for the mechanical properties of cylindrical specimens in appendices, and also adds axial tensile tests, concrete-to-rebar grip strength tests , Concrete bond strength test, concrete Poisson’s ratio test, concrete wear resistance test, hardened concrete density test, water absorption test and test methods for concrete physical and thermal properties.

Test method for mechanical properties of concrete

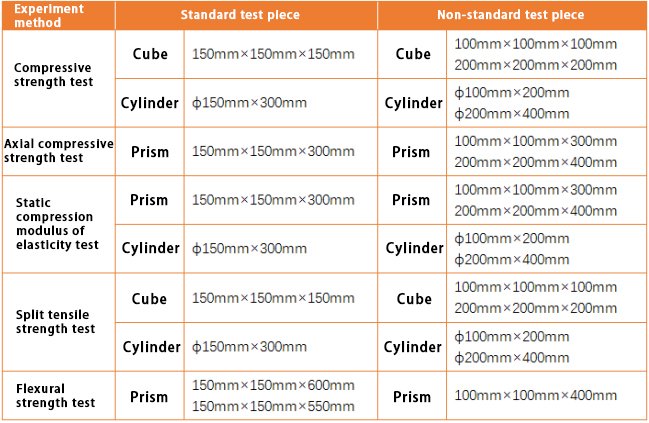

GB/T50081 contains 5 test methods for concrete mechanical properties: compressive strength test, axial compressive strength test, elastic modulus test under static compression, splitting tensile strength test, and flexural strength test.

Specimen shape and size requirements:

Pressure testing machine requirements:

The failure load of the specimen should be greater than 20% of the full scale of the press and should be less than 80% of the full scale of the press;

The relative error of the indication value should be ±1%;

There should be a loading speed indicating device or a loading speed control device, and should be able to load evenly and continuously

The flatness tolerance of the upper and lower bearing plates of the testing machine should not be greater than 0.04mm; the parallelism tolerance should not be greater than 0.05mm; the surface hardness should not be less than 55HRC; the plate surface should be smooth and flat, and the surface roughness Ra should not be greater than 0 .80μm;

The ball seat should rotate flexibly; the ball seat should be placed on the top surface of the specimen with the convex side facing upwards.

Concrete performance test

Static compression elastic modulus test:

To determine the elastic modulus of the cylinder specimen under static compression, the standard specimen is a cylinder specimen of ф150mm×300mm; the cylinder specimens of ф100mm×200mm and ф200mm×400mm are non-standard specimens.

Poisson’s ratio test:

This method uses prismatic specimens (150mm×150mm×300mm), which can be measured simultaneously with the same group of specimens for the elastic modulus of static compression. The pressure testing machine has the same requirements as the mechanical property testing equipment.

Axial Tensile Test:

The size of the middle section of the test piece should be 100mm × 100mm, and the core test piece should be a cylinder with a diameter of 100mm.

Tensile testing machine requirements: the failure load of the specimen should be greater than 20% of the full scale of the tensile testing machine and less than 80% of the full scale of the tensile testing machine; the relative error of the indication value should be ±1%; there should be a loading speed indicating device or a plus Loading speed control device, and should be able to load evenly and continuously; the stretching distance should not be less than 800mm ~ 1000mm.

Grip strength test of concrete and steel bars:

The size of the tryout should be 150mm×150mm×150mm.

The tensile testing machine should meet the following requirements: the failure load of the specimen should be greater than 20% of the full scale of the tensile testing machine and should be less than 80% of the full scale of the tensile testing machine; the relative error of the indication value should be ±1%; there should be an indication of the loading speed device or loading speed control device, and should be able to load evenly and continuously.

Concrete bond strength test:

This method is suitable for determining the bond strength between old and new concrete. Three cubes of 150mm×150mm×150mm were formed using the raw materials and mix ratios similar to those of the bonded concrete. The test equipment is the same as the splitting tensile strength test requirements.

Wear resistance test:

The test methods are divided into wear volume method and crater length method.

The wear method is suitable for measuring the wear amount per unit area on the wear surface of the concrete specimen, and a 150mm×150mm×150mm cube specimen is used.

The grinding pit length method is suitable for measuring the grinding pit length of concrete specimens under the action of friction steel wheels and abrasives, and the cube specimens not less than 100mm×100mm×100mm are used.

Hardened concrete density test:

It is suitable for the determination of apparent density, original bulk density, water-saturated bulk density and drying bulk density of hardened concrete.

The test piece should be a cube or prismatic test piece with a side length of not less than 100mm; when a cored test piece is used, the diameter of the test piece should not be less than 100mm, and the height should not be less than 100mm; the minimum volume of the test piece should not be less than 50D3, D is the maximum particle size of the coarse aggregate.

Water absorption test:

The test piece should be a cube test piece, the standard test piece should be a cube test piece with a side length of 100mm, and the cube test piece of other sizes is a non-standard test piece; when a core drill test piece is used, the standard test piece is a cylinder of ф100mm×100mm Body specimens, other sizes of cylindrical specimens are non-standard specimens; the minimum volume of the specimen should be greater than 50D3, and D is the maximum particle size of the coarse aggregate.