Ultrasonic Pulse Velocity (UPV) is an effective non-destructive testing (NDT) method for quality control of concrete materials and detecting damages in structural components. The UPV methods have traditionally been used for the quality control of materials, mostly homogeneous materials such as metals and welded connections. With the recent advancement in transducer technology, the test has been widely accepted in testing concrete materials. Ultrasonic testing of concrete is an effective way for quality assessment and uniformity, and crack depth estimation. The test procedure has been standardized as “Standard Test Method for Pulse Velocity through Concrete” (ASTM C 597, 2016).

How does it work?

The concept behind the technology is measuring the travel time of acoustic waves in a medium, and correlating them to the elastic properties and density of the material. Travel time of ultrasonic waves reflects the internal condition of the test area. In general, for a given trajectory, higher travel time is correlated to low quality concrete with more anomalies and deficiencies, while lower travel time is correlated to high-quality concrete with fewer anomalies. Once the ultrasonic wave spreads within the test area, the wave is reflected in the boundary of anomalies resulting in higher travel time. This results in higher transmission time (lower wave speeds) in poor quality concrete and lower transmission time (higher wave speed) in good quality concrete.

Different configurations of transducers can be used to perform a UPV test. This includes direct transmission, semi-direct transmission, and indirect (surface) transmission. Different configurations of transducer based on the access to the surface of the test area. The ultrasonic velocity is prone to signal travel trajectory that is defined by the transducer configurations.

Couplant —Transducer

The UPV transducers must be in full contact with the concrete surface; otherwise, the air pocket between the transducer and concrete may result in measurement error (i.e. inaccurate measurement of transit time). One reason is that only a negligible amount of wave energy will be transmitted in poor contact. Different couplants can be used to eliminate air pockets and to assure good contact (e.g. petroleum jelly, grease, liquid soap, and kaolin-glycerol paste). It is recommended to make the couplant layer as thin as possible.

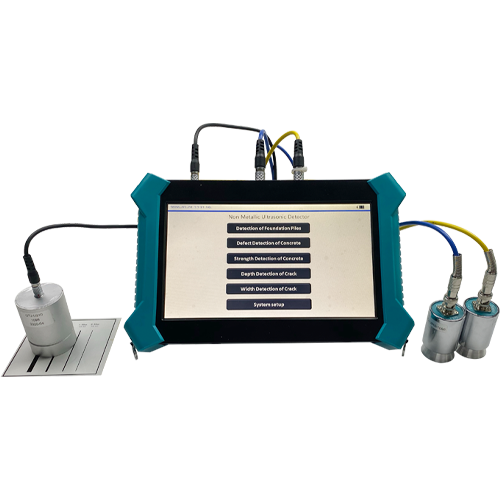

U630 Digital Ultrasonic Flaw Detector

U600 Digital ultrasonic flaw detector and thickness measurement integrated machine integrated ultrasonic flaw detection, ultrasonic thickness measurement, and ultrasonic penetration functions in one. It has various functions such as ultrasonic thickness gauge, WIFI connection network or mobile phone, HDMI, digital filtering, etc., applicable Ultrasonic testing for the surface and internal defects of metal and non-metal materials in the industrial field. The design meets the requirement of ergonomics and is simple, intuitive, convenient, and practical. Provides a very high level of flaw detection with simple basic operations, which makes ultrasonic flaw detectors easy to use for both experienced and novice industry personnel.

2 Responses

Thanks for such interesting blog! That really helped a lot and tells a lot about ultrasonic concrete testing equipment

Outstanding blog post! The discussion on ultrasonic concrete testing was incredibly informative. I appreciate how you explained its benefits in accurately assessing concrete properties and identifying potential issues. Thanks for sharing this valuable knowledge!