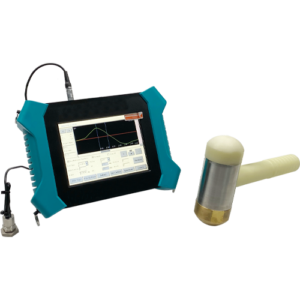

U600 Digital ultrasonic flaw detector and thickness measurement integrated machine integrated ultrasonic flaw detection, ultrasonic thickness measurement, and ultrasonic penetration functions in one. It has various functions such as ultrasonic thickness gauge, WIFI connection network or mobile phone, HDMI, digital filtering, etc., applicable Ultrasonic testing for the surface and internal defects of metal and non-metal materials in the industrial field. The design meets the requirement of ergonomics and is simple, intuitive, convenient, and practical. Provides a very high level of flaw detection with simple basic operations, which makes ultrasonic flaw detectors easy to use for both experienced and novice industry personnel.

| Working principle | Ultrasound (pulse-echo/ echo-echo) |

|---|---|

| Working frequency range | 0.5 ~ 20MHz |

| Detection range | 0 ~ 14000 (steel longitudinal wave) mm |

| Pules displacement | -45 a 1000 (steel longitudinal wave) mm |

| Detection method | Negative wave, forward wave, two-way wave, filtering, RF wave |

| Vertical linear error | ≤3% |

| Horizontal linear error | ≤0.5% |

| Operating voltage | 12V (battery, DC) |

| Storage | Expansion TF card, mass storage |

USAGE OVERVIEW

U600 Digital ultrasonic flaw detector and thickness measurement integrated machine integrated ultrasonic flaw detection, ultrasonic thickness measurement, and ultrasonic penetration functions in one. It has various functions such as ultrasonic thickness gauge, WIFI connection network or mobile phone, HDMI, digital filtering, etc., applicable Ultrasonic testing for the surface and internal defects of metal and non-metal materials in the industrial field. The design meets the requirement of ergonomics and is simple, intuitive, convenient, and practical. Provides a very high level of flaw detection with simple basic operations, which makes ultrasonic flaw detectors easy to use for both experienced and novice industry personnel.U600 brings together modern high-tech such as ultrasonic flaw detection, thickness measurement, computer, electronics, mold, technology, etc., to achieve the perfect combination of this high-tech. It provides the industry with more superior performance and more powerful machines, which can be widely used in various fields such as petroleum, chemical industry, metallurgy, shipbuilding, aviation, and aerospace.

PRODUCT FEATURES

Technical Parameter

| Item | U610 |

| Working principle | Ultrasound (pulse-echo/ echo-echo) |

| Working frequency range | 0.5 ~ 20MHz |

| Pulse width | Square wave width 30~1000ns adjustable, step 0.1ns |

| Detection range | 0 ~ 14000 (steel longitudinal wave) mm |

| Pules displacement | -45 a 1000 (steel longitudinal wave) mm |

| Material sound velocity | 300 ~ 15000m/s |

| Detection method | Negative wave, forward wave, two-way wave, filtering, RF wave |

| Gain adjustment | 0 a 110dB: 0.1 / 1/2/6 step adjustment |

| Valve | Off/incoming wave/ lost wave |

| DAC, AVG function | DAC curve, AVG curve |

| Attenuator error | Every 12dB ± 1dB |

| Vertical linear error | ≤3% |

| Horizontal linear error | ≤0.5% |

| Dynamic range | ≥30dB |

| Flaw detection margin | ≥65(2.5Z20N probe)dB |

| Far-field resolution | ≥26dB |

| Electrical noise level | ≤10(1~4MHz)% |

| Equivalent input noise | <80×10-9V/√Hz |

| Pulse repetition frequency | 20~1000Hz, step 1 Hz |

| Pulse voltage | 25~400V adjustable, step 25V |

| Thin plate resolution | ≤3(5C10N probe)mm |

| AWS D1.1 / D1.5 | American Welding Association AWS D1.1 / 1.5 calculates steel structure and bridge weld grades |

| Operating voltage | 12V (battery, DC) |

| Storage | Expansion TF card, mass storage |

We will contact you within 1 working day, please pay attention to the email with the suffix “@gtj-test.com”.